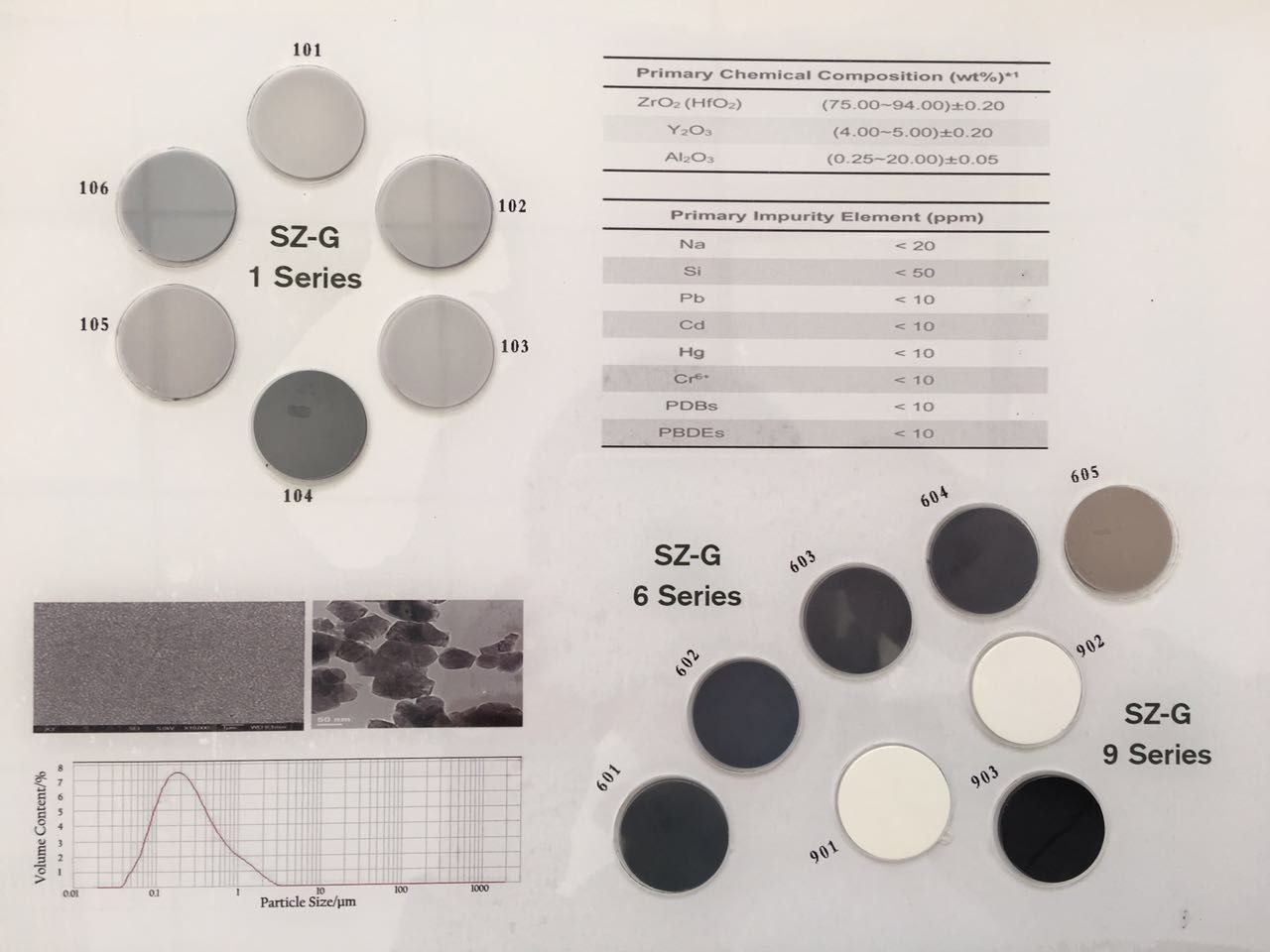

Name. | Colored zirconia powder | ||||||

Desc. | Color can be customized | ||||||

Tightly sealed with plastic film in PP drum. | |||||||

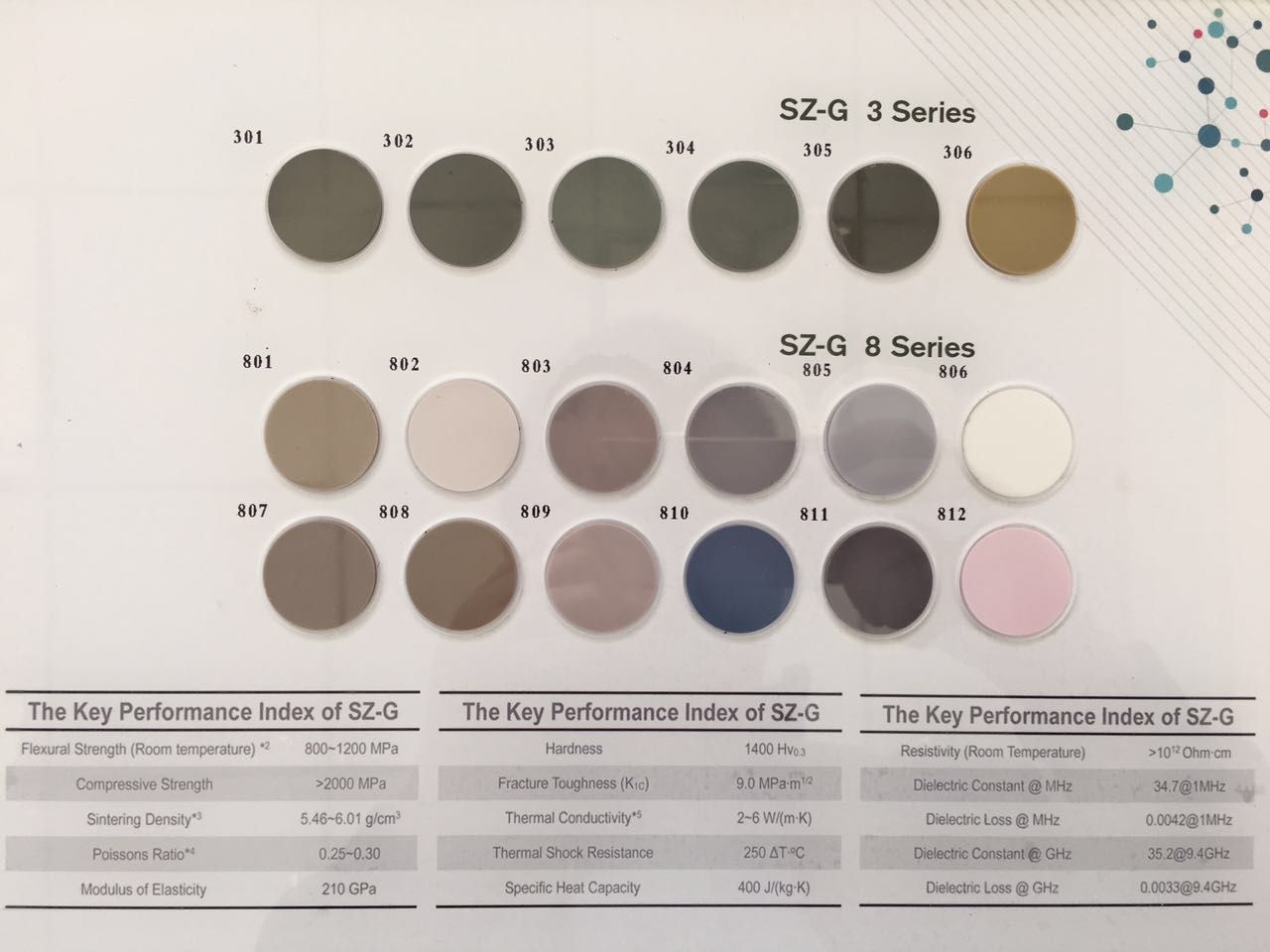

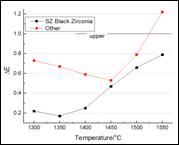

Products processed with SZ-CZ series powders which using stable crystal as colorant have the advantages of good color evenness, good color accuracy and shinning like natural jewel, also with the characteristic of wide sintering range, high strength, high hardness, good electromagnetic and no pinholes defects. For our ZMA powder, alumina uniformly dispersed in zirconia matrix, provide the sintered body with decreased transparency and specific gravity without reduce the excellent strength of zirconia. The product processed with this powders have the characteristic of no pinhole, easily grinding and shinning like natural jewel after polishing. | |||||||

App. | Both series powders can be customized with binder and feedstock applied for dry-press,isostatic press, injection and tape casting.it is idea raw materials for smart wearable ceramic product and ceramic shell for phones. |

| |||||

Spec. | Grade | D50 | BET | Temp | Strength | Density | |

SZ-CZ | 0.7-0.9μm | 5-12(m2/g) | 1450℃ | ≥1000Mpa | ≥5.99g/cm3 | ||

SZ-ZMA | 0.7-0.9μm | 14-16(m2/g) | ≥800Mpa | ≥5.5g/cm3 | |||

For ZMA, ZrO2(HfO2)wt% =79-81%;For SZ-CZ ZrO2(HfO2)+Y2O3wt% ≥94%,All impurities such as Si, Fe, Na are controlled below 100ppm | |||||||

Photos. |

Series of grey, blue and black color |

Series of pink, green and other color | |||||

Excellent color stability under high temp. |

Uniform distribution of grain and colorant | ||||||

Remark. | Information showed above only for reference, prevail with the agreed quality standards after sale. Carefully read the MSDS document before using; Process performance may not be suitable for some specific circumstances, please contact our company professional guidance; | ||||||

Colored zirconia powder

Prev:No more.

Next:No more.